One year ago, Flyability introduced its groundbreaking drone, the Elios 2. Since then, we've been eager to hear from users about their experiences and how this technology has transformed industrial inspections.

In this article, we take a closer look at the advancements in drone technology for industrial use in 2019 and share initial feedback from industries, users, and pilots who have been using the Elios 2 in real-world scenarios over the past year.

2019—A Turning Point for Robotics in Industrial Inspections

Looking back, 2019 marked a significant milestone in the adoption of robotics for inspections. More and more large industrial companies are now integrating drones into their operations. As reported by Bloomberg in an article titled "Drones Do Deadly Work So You Don’t Have To," companies like Dow, At&T, BASF, and Shell are using drones to enhance safety, reduce risks, and cut costs. Among these developments, we're especially proud to see drones making a big difference in confined space inspections. For example, Dow reported eliminating 1,000 confined space entries thanks to robotic solutions, while LafargeHolcim included drones as a key part of its “Plants of Tomorrow†initiative. For Flyability, 2019 was all about the launch of the Elios 2—a drone designed for a wide range of indoor applications. It’s user-friendly and allows even new pilots to feel confident and experienced right from the start. The Elios 2 represents a major leap forward in indoor inspection robotics. Its features, such as oblique lighting, distance lock, and intuitive controls, were developed based on direct feedback from inspectors across various industries that rely on RVI (Remote Visual Inspection) tools daily.2020 and Beyond—How Drones Are Supporting Inspections Today

Over the past year, many of our customers have shared their success stories and accomplishments with us. Here are some of the most impressive examples:Oil & Gas / Maritime

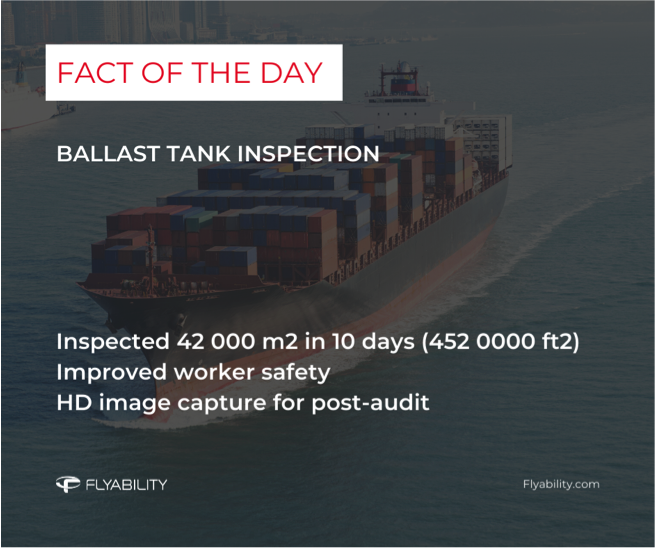

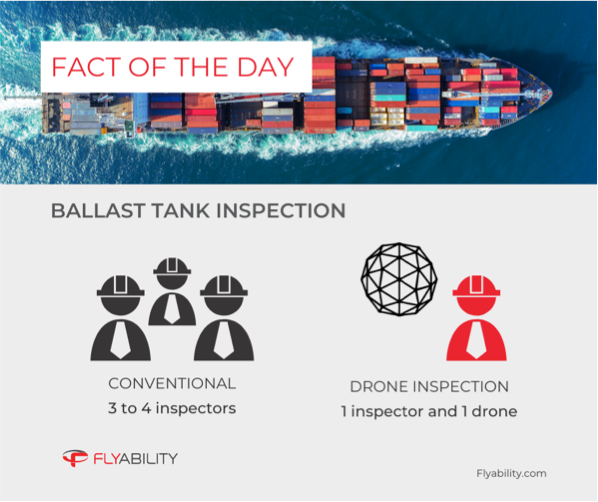

Bureau Veritas France used the Elios 2 for a ballast tank inspection for Total. The results were faster, safer, and produced high-quality HD images that could be reviewed after the mission.

Power Generation

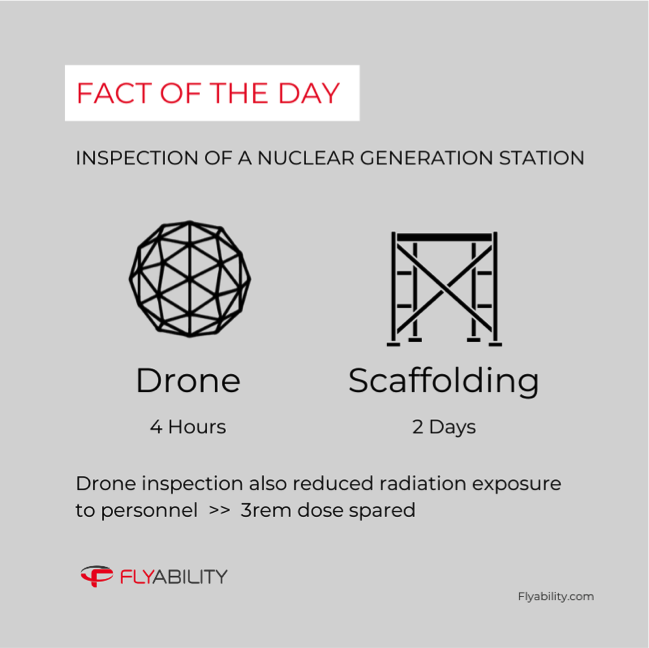

Exelon Clearsight used the Elios 2 to inspect a radioactive and hazardous confined space, reducing the time from two days to just four hours. This not only improved safety but also boosted efficiency.

Maritime

Our US partner MFE Rentals conducted a ballast tank inspection using one pilot and three short flights. Traditionally, this would require multiple inspectors with ropes and safety equipment. The Elios 2’s collision tolerance and built-in lighting made the process much simpler and safer.

Indoor Photogrammetry—Mining & Beyond

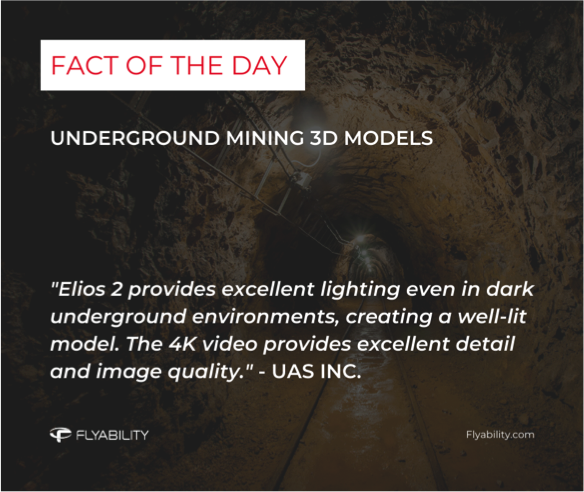

UAS Inc., a mining inspection company, used the Elios 2 for underground photogrammetry. Users have praised the drone for its ability to capture detailed data in dark, GPS-denied environments.

Drone Usage and Development

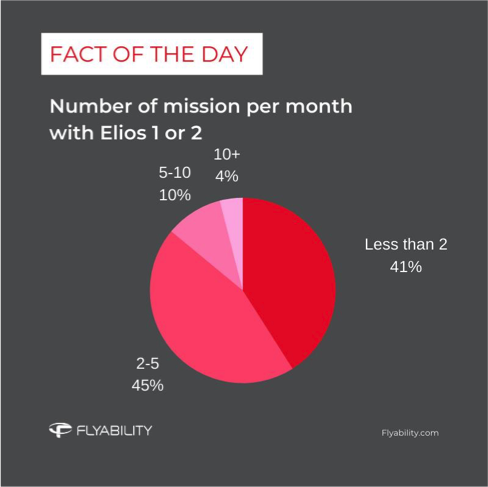

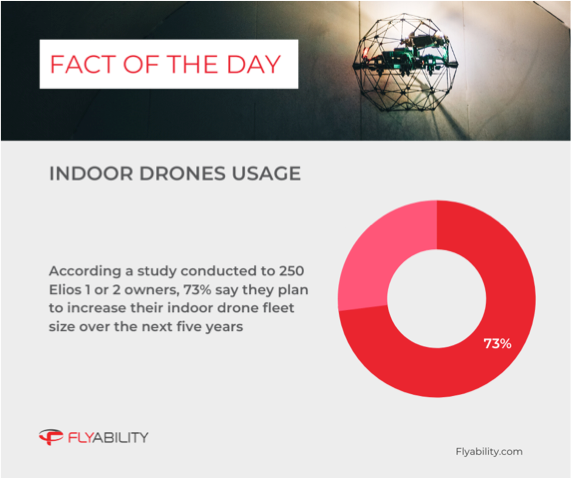

Many asset owners are seeing a clear return on investment from drones, even with just a few missions per month. In a survey of 250 Elios 1 and 2 users, 45% performed 2–5 missions monthly, and 41% did fewer than 2.

Creasing Rule,Creasing Rule For Flat Bed,Flat Bed Cutting 2Pt,3Pt 23.3Mm Creasing Rule

Jiangyin Mitoo Precise Co.,Ltd. , https://www.mitoosteel.com