Centrifugal Wheelblast vs. Air Blasting: Which One Fits Your Needs?

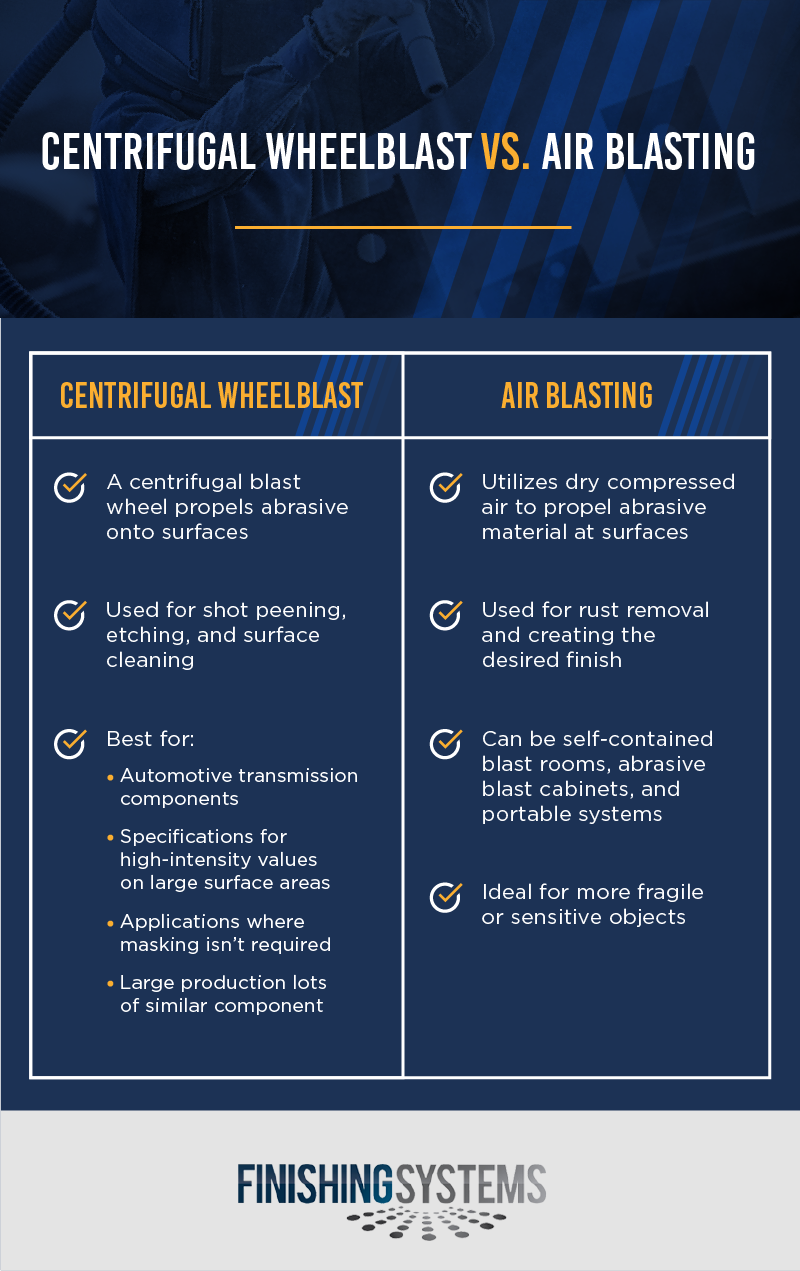

Last Updated: October 17, 2023Deciding whether to go with a wheel blast or an air blast setup can be a tough choice, especially if you're not sure what each method offers. Both types of abrasive blasting aim to clean, descale, or modify the surface of metal components. However, factors like the size, shape, and quantity of your parts play a critical role in determining which blasting method is best for achieving your desired results. Choosing the right equipment, process, and media ensures that your components get the precise finish they need in the most efficient and cost-effective way possible.

With numerous options available in terms of blasting materials and techniques, it's easy to feel overwhelmed. If you're torn between wheel blasting and air blasting, this guide should help clarify which approach suits your specific requirements.

Feel free to reach out to us if you have any questions!

Understanding Wheel Blasting

Wheel blasting relies on a centrifugal blast wheel to hurl abrasive particles toward the surface of your parts. This technique is commonly used for tasks such as shot peening, etching, and thorough cleaning. Unlike air blasting, which uses compressed air to push abrasive materials, wheel blasting employs mechanical force generated by the spinning wheel to accelerate the abrasive media.

Modern wheel blast wheels come in two primary configurations: direct-driven and belt-driven models, each supported by a robust bearing system. The rotational speed of the wheel directly impacts the performance and duration of the blasting cycle. Variable frequency drives (VFDs) allow users to fine-tune the wheel speed according to their needs.

Key considerations when choosing wheel blasting include:

- Perfect for automotive components like gears, shafts, leaf springs, and axle beams

- Best suited for large-scale projects requiring uniform treatment over extensive areas

- Ideal for applications where masking isn't necessary and the whole surface must be processed

- Highly effective for high-volume runs of identical parts

In a typical wheel blast operation, abrasive material—often steel shot or grit—is fed into the machine while the parts are loaded inside the chamber. As the wheel spins rapidly, it creates centrifugal force, propelling the abrasive evenly across all exposed surfaces of the components. This method works particularly well for smaller batches of multiple small items or larger standalone objects. Thanks to its quick cycle times, wheel blasting can handle substantial quantities efficiently.

This process works exceptionally well with metallic abrasives such as steel shot or grit, as well as non-metallic options like aluminum or zinc cut wire.

Exploring Air Blasting

On the other hand, air blasting leverages compressed air to direct abrasive particles toward the target surface. Compressed air serves as the driving force behind this technique, pushing the abrasive through nozzles aimed at the workpiece. Air blasting finds utility in diverse fields, ranging from rust removal to achieving specialized finishes.

Air blast systems fall into several categories, including self-contained blast rooms, enclosed cabinets (both direct-pressure and suction-type), and portable units. Effective dust management within these setups ensures cleaner workspaces and improved visibility during operations.

Comparing Wheel Blasting and Air Blasting

Both wheel blasting and air blasting serve valuable purposes in industrial settings, but they excel under different circumstances. Understanding their respective strengths will aid in selecting the optimal solution for your particular situation.

One major advantage of wheel blasting lies in its speed and cost-effectiveness, especially when dealing with large-scale projects involving heavy-duty materials. Its ability to cover broad areas uniformly makes it ideal for treating extensive surfaces without requiring additional shielding measures. Additionally, wheel blasting tends to be more economical per unit when processing大批é‡çš„相åŒéƒ¨ä»¶ã€‚

Conversely, air blasting shines in scenarios demanding precision and delicacy. For instance, intricate designs or fragile components may benefit from the controlled stream provided by an air blast cabinet. By adjusting variables such as air pressure and abrasive type, operators can tailor the outcome to meet exact specifications.

Seek Expert Guidance for Your Specific Requirements

If you remain undecided about which method aligns best with your goals—or if you're considering acquiring new equipment—look no further than Finishing Systems. Our comprehensive range of blasting and finishing solutions caters to various industries, ensuring that you receive tailored recommendations based on your unique demands.

For further insights, don't hesitate to contact us today!

Fireproof Special Silicone Sealant

Fireproof and flame retardant special silicone sealant, Fireproof special silicone sealant, Fireproof silicone sealant

Shandong Gufeng Technology Co., LTD. , https://www.gfkjgs.com