What is Stockpile Measurement?

Stockpile measurement is a method used to determine the size, volume, or weight of materials stored in large quantities. This technique is essential for businesses that deal with bulk goods, as it allows them to accurately track their inventory and manage resources efficiently.

Many industries, such as mining, construction, and agriculture, rely on stockpiles of raw materials stored at specialized facilities. These piles are often created by trucks, moved by heavy machinery, and managed by workers. But how do companies know exactly what they have? Traditionally, manual methods and GPS systems were used, but these were often inaccurate and time-consuming.

Today, advanced technologies like drones, LiDAR, and photogrammetry have revolutionized stockpile measurement. Companies can now gather precise data quickly, which improves productivity, reduces waste, and cuts costs across the board.

Sulfur stockpile

Sulfur stockpile

Why Is Stockpile Measurement Important?

Accurate stockpile measurement is crucial for businesses in various industries. Whether you're dealing with coal, ores, fertilizers, or industrial dust, knowing the exact volume of your stockpiles helps reduce costs and improve efficiency.

Here are some key reasons why stockpile measurement matters:

It Increases Profitability and Efficiency

Manual estimation can lead to waste and inefficiencies. If workers guess the amount of material in a stockpile, it's easy to over-order or underutilize resources. Accurate measurements help companies manage inventory better, reducing excess stock and associated costs.

With real-time data, businesses can plan production schedules, order materials when needed, and optimize labor and machine usage. This leads to better decision-making, higher productivity, and increased profits.

It Provides Useful Data for Business Decisions

Modern stockpile measurement tools generate accurate data that can be used for financial reporting, tax calculations, and securing loans. The more precise the data, the easier it is to present to external stakeholders, such as banks or regulatory bodies.

Companies can also use this data to track inventory changes, monitor compliance, and ensure transparency in operations. This makes it easier to manage resources and meet legal requirements.

It Helps Meet Regulatory Requirements

Many industries must comply with environmental and safety regulations. For example, the EU Emissions Trading System requires businesses to calculate CO2 emissions through mass balances, which is made easier with accurate stockpile data.

Regulators appreciate transparency and precision. When a company uses reliable measurement tools, it shows commitment to compliance and accountability, making inspections and audits smoother and more efficient.

It Improves Workplace Safety

Stockpile measurement not only saves money but also protects workers. Traditional methods often require employees to manually measure large or hazardous piles, which can be dangerous. Drones and other automated tools reduce the need for human intervention in risky environments.

By using technology, companies can prevent accidents, minimize exposure to harmful materials, and ensure safer working conditions for all staff involved.

What Industries Use Stockpile Measurement?

Stockpile measurement is widely used across multiple sectors, including:

Aggregates

Aggregates like sand, gravel, and crushed stone are essential in construction. Managing these materials requires accurate measurements to ensure the right mix is always available. Stockpile measurement helps prevent contamination and ensures efficient use of resources.

Stockpile aggregates

Proper management of aggregate stockpiles helps maintain quality and avoid delays in construction projects.

Construction

Construction companies rely on stockpile measurement to manage materials like sand, dirt, and concrete. Accurate data helps plan hauling routes, allocate resources, and improve site efficiency.

This also enhances worker safety, as drivers and operators can better understand what they’re working with before starting their tasks.

Mining

Mining operations depend heavily on stockpile measurement to track ore and mineral reserves. Drones and LiDAR provide fast, accurate data, helping companies manage large sites safely and efficiently.

Quarry mine stockpiles

Quarry mine stockpiles

These tools also help reduce the risks associated with manual measurements, especially in hazardous environments.

Recycling

In recycling and waste management, stockpile measurement is vital for tracking materials like industrial dust and scrap metal. Accurate data helps companies manage inventory, meet legal standards, and improve operational efficiency.

A case study showed that one company improved its inventory accuracy by over 200% using drone-based measurement techniques.

Shipping and Ports

Ports and shipping centers handle massive volumes of bulk materials daily. Accurate stockpile measurement is essential for managing cargo, optimizing storage, and ensuring smooth logistics.

Stockpile measurement in shipping and ports

Stockpile measurement in shipping and ports

Even small inaccuracies can lead to costly errors in fuel, time, or resource allocation, making precision critical in this sector.

Stockpile Measurement Methods

There are several ways to measure stockpiles, each with its own advantages and limitations. Here are the most common methods:

Manual Measurement

Traditional methods like walking wheels or tape measures are still used, though they are less accurate and time-consuming. These methods are prone to error and are rarely used in modern operations due to the availability of more advanced tools.

Traditional stockpile measurement with a walking wheel and tape measure

Traditional stockpile measurement with a walking wheel and tape measure

Smartphone Apps

Many smartphone apps now allow users to measure stockpiles by capturing images and videos. These tools are cost-effective and easy to use, providing accurate results in a short time.

One popular app, Stockpile Lite, lets users walk around a pile and upload footage for analysis. It’s ideal for companies looking for a budget-friendly solution without sacrificing too much accuracy.

Stockpile Lite app

Stockpile Lite app

Photogrammetry

Photogrammetry involves taking multiple photos and creating a 3D model of a stockpile. This method is highly accurate but can be expensive and requires skilled operators.

Drone footage on left, photogrammetry 3D model on right

Drone footage on left, photogrammetry 3D model on right

Despite the cost, photogrammetry provides detailed and reliable data, making it suitable for large-scale operations.

LiDAR

LiDAR (Light Detection and Ranging) uses laser light to create highly accurate 3D maps of stockpiles. It is particularly useful in low-light conditions and offers greater precision than photogrammetry in certain scenarios.

LiDAR systems can be mounted on drones or handheld devices, making them versatile for different environments. However, they are typically more expensive and require specialized equipment.

Drones for Stockpile Measurement

Drones have become one of the most effective tools for stockpile measurement. They can carry cameras, LiDAR sensors, and photogrammetry equipment, allowing for fast and accurate data collection.

For indoor applications, drones like the Elios 3 are designed to operate in dark and dusty environments. In outdoor settings, drones with long battery life and multiple payloads are ideal for covering large areas efficiently.

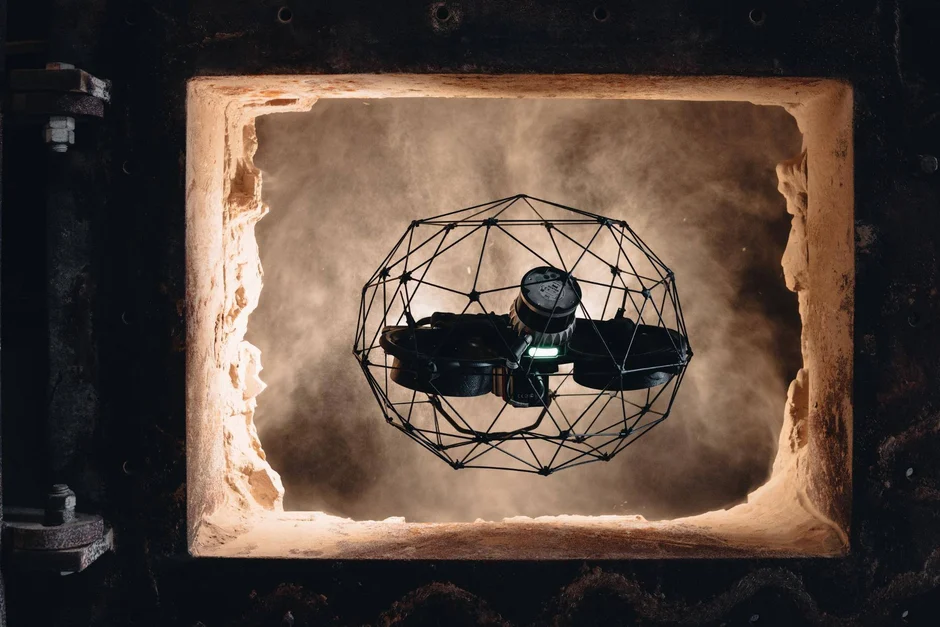

The Elios 3 entering an industrial asset for an inspectionÂ

The Elios 3 entering an industrial asset for an inspectionÂ

For example, the Elios 3 has been used in mining and cement plants to measure stockpiles in challenging environments. Its ability to complete surveys quickly and accurately has made it a valuable tool in many industries.

BENEFITS OF DRONES FOR STOCKPILE MEASUREMENT

- Speed: Drones can cover large areas in minutes, significantly reducing survey time compared to manual methods.

- Accuracy: Equipped with advanced sensors, drones provide centimeter-level precision, improving data reliability.

- Cost-Efficiency: While initial investment may be high, the long-term savings from reduced waste and improved planning make drones a smart choice.

- Safety: By minimizing human exposure to hazardous environments, drones help protect workers and reduce accident risks.

UPGRADING STOCKPILE MEASUREMENT TECHNIQUES THANKS TO DRONES

Drones equipped with LiDAR and photogrammetry offer a new level of accuracy and efficiency in stockpile management. Digital models of stockpiles allow for better reporting, communication, and tracking, helping businesses avoid mistakes and improve decision-making.

The Elios 3, for instance, has proven to be a game-changer in industries like mining and construction. With its ability to collect data quickly and safely, it represents a major advancement in how companies manage their inventory.

As technology continues to evolve, the use of drones for stockpile measurement will likely become standard practice, offering a safer, faster, and more accurate way to manage bulk materials.

Small Cylinder Magnets,Small Bar Magnets,Neodymium Cylinder Magnets,Rare Earth Cylinder Magnets

Anfeng Industrial Co.,Ltd , https://www.afmagnets.com