What is Stockpile Measurement?

Stockpile measurement is a process used to determine the size, volume, or weight of a stockpile of materials. This technique is crucial for businesses that deal with large quantities of raw materials, such as in mining, construction, and agriculture.

These materials are often stored in large piles at dedicated storage facilities. The piles are created by trucks, moved by bulldozers, and managed by workers. But how do managers know exactly what they have on hand? In the past, manual methods and GPS systems were used, but these had limited accuracy and often led to estimation errors.

Today, new technologies like drones, LiDAR, and photogrammetry have revolutionized stockpile measurement. These tools provide hyper-accurate data, helping companies improve efficiency, reduce costs, and make better-informed decisions.

Sulfur stockpile

Sulfur stockpile

Why Is Stockpile Measurement Important?

Accurate stockpile measurement plays a vital role across many industries. Whether it's coal, fertilizers, ores, or industrial dust, knowing the exact volume helps businesses save money, improve efficiency, and streamline operations.

Here are some key reasons why stockpile measurement matters:

It Increases Profitability and Efficiency

When workers estimate stockpile sizes manually, it's easy to over-order or under-utilize materials. This leads to waste and lost profits. With accurate measurement tools, companies can optimize inventory, avoid excess stock, and manage resources more effectively.

Additionally, precise data allows for better planning of production schedules, machine maintenance, and workforce management. This not only cuts costs but also improves overall productivity and profitability.

It Provides Usable and Reliable Data

Modern stockpile measurement technologies generate high-quality data that can be used for financial reporting, tax purposes, and securing loans. Accurate measurements give businesses transparency and confidence when presenting data to external stakeholders.

This kind of data is essential for compliance, audits, and regulatory reporting. It ensures that companies can operate efficiently while maintaining proper documentation and accountability.

It Helps Meet Regulatory Standards

Many industries must adhere to strict regulations, especially in environmental and safety compliance. For example, the EU Emissions Trading System requires accurate mass balance calculations, which are made easier through precise stockpile management.

Regulators value transparency and accuracy, and reliable stockpile data ensures that businesses meet their obligations without guesswork or manipulation.

It Enhances Worker Safety

Manual stockpile measurements can be dangerous, especially in environments with unstable piles or hazardous materials. Using drones and other automated tools reduces the need for workers to physically inspect risky areas.

This not only prevents accidents but also makes the workplace safer and more efficient. With less time spent in hazardous conditions, worker satisfaction and productivity can both improve.

Below is a 3D fly-through of salt stockpiles in a mine, captured using LiDAR technology from the Elios 3 drone. This video highlights how modern tools can safely and accurately measure even the most challenging stockpiles.

Large stockpiles of dust, stone, or fertilizer can be unpredictable and dangerous for workers to approach. Drones and robotic systems eliminate this risk, making the process safer and more efficient.

Which Industries Use Stockpile Measurement?

Stockpile measurement is widely used in various sectors, including:

Aggregates

Aggregates like sand, gravel, and crushed stone are essential in construction. Managing these materials requires precise stockpile measurements to ensure the right mix is available for different projects.

Stockpile aggregates

Proper measurement helps prevent cross-contamination and ensures that each project gets the correct material mix. It also protects against damage from weather and erosion.

Construction

Construction companies rely on stockpile measurement to manage materials like sand, wood chips, and concrete. Accurate data helps plan hauling routes and allocate labor efficiently.

With real-time data, site managers can make informed decisions about material movement and usage, improving safety and reducing delays.

Mining

Mining operations use stockpile measurement to track ore and mineral reserves. Drones and LiDAR help monitor large, complex stockpiles with high precision and minimal risk to workers.

Quarry mine stockpiles

Quarry mine stockpiles

These tools are especially useful in remote or hazardous locations where manual measurement is impractical or unsafe.

Recycling

In recycling and waste management, accurate stockpile data helps companies track materials and comply with environmental regulations. Drones and photogrammetry enable fast and safe inspections of large stockpiles.

This ensures that waste is properly managed and that companies can meet legal requirements for storage and disposal.

Shipping and Ports

Ports and shipping centers handle massive amounts of bulk cargo, such as grains, minerals, and chemicals. Accurate stockpile measurements are critical for managing logistics and ensuring smooth operations.

Stockpile measurement in shipping and ports

Stockpile measurement in shipping and ports

Even small inaccuracies can lead to significant losses in fuel, time, or money. Therefore, accurate and timely measurements are essential in this industry.

Stockpile Measurement Methods

There are several ways to measure stockpiles, each with its own level of accuracy and suitability for different situations. Here are the most common methods:

Manual Measurement

Traditional manual methods include using a walking wheel, measuring by truckload, or estimating visually. While these are low-cost, they are also highly inaccurate and prone to human error.

Traditional stockpile measurement with a walking wheel and tape measure

Traditional stockpile measurement with a walking wheel and tape measure

These methods are rarely used today due to their limitations, but they may still be found in small-scale operations.

Smartphone Apps

Smartphones can now serve as effective tools for stockpile measurement. With the right apps, users can capture images or videos of a pile and get accurate volume estimates quickly.

Stockpile Lite app

Stockpile Lite app

These solutions are cost-effective and suitable for smaller operations or those looking for a quick, affordable option.

Photogrammetry

Photogrammetry uses multiple images to create 3D models of stockpiles. This method is highly accurate and provides detailed data, but it can be expensive and requires specialized equipment and expertise.

Drone footage on left, photogrammetry 3D model on right

Drone footage on left, photogrammetry 3D model on right

It’s ideal for large-scale operations that require consistent and precise measurements over time.

LiDAR

LiDAR technology uses laser pulses to create highly accurate 3D maps of stockpiles. It works well in low-light conditions and is often used in conjunction with drones.

While LiDAR offers superior accuracy, it is also one of the most expensive options. It is best suited for companies with larger budgets and complex measurement needs.

Drones for Stockpile Measurement

Drones are among the most effective tools for collecting stockpile data. They can carry cameras, photogrammetry sensors, and LiDAR equipment, making them versatile for different environments.

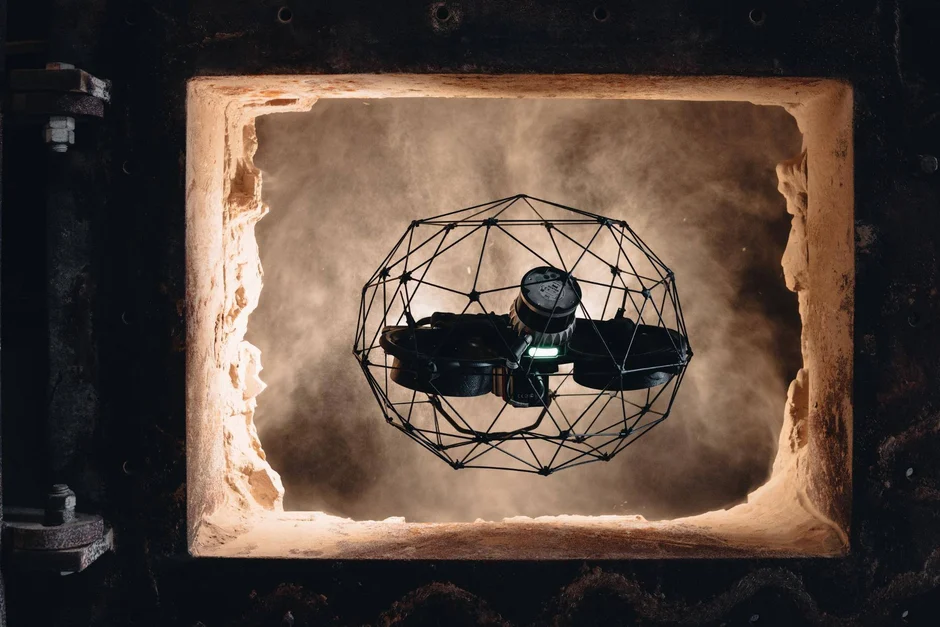

For indoor stockpiles, a compact drone like the Elios 3 is ideal. It can navigate dark and dusty spaces, providing accurate data without putting workers at risk.

The Elios 3 entering an industrial asset for an inspectionÂ

The Elios 3 entering an industrial asset for an inspectionÂ

The Elios 3 has been used in various industries, including mining, cement, and construction. For example, it was used to measure stockpiles in a clinker silo, a challenging environment that traditional methods could not easily access.

Outdoor stockpiles benefit from drones with long battery life and multiple flight capabilities. These drones can cover large areas quickly and efficiently, reducing the need for manual surveys.

BENEFITS OF DRONES FOR STOCKPILE MEASUREMENT

- Speed: Drones can cover large areas in minutes, significantly reducing the time needed for surveys.

- Accuracy: Equipped with advanced sensors, drones provide precise measurements that are hard to achieve manually.

- Cost: Although initial investment is higher, the long-term savings from reduced labor and improved efficiency make drones a smart choice.

- Safety: By minimizing direct exposure to hazardous stockpiles, drones protect workers and reduce the risk of accidents.

UPGRADING STOCKPILE MEASUREMENT TECHNIQUES THANKS TO DRONES

Drones equipped with LiDAR or photogrammetry offer a powerful solution for modern stockpile management. They allow companies to collect accurate, visual data that can be used for reporting, communication, and tracking changes over time.

The Elios 3, for instance, streamlines complex stockpile measurements and enhances safety, speed, and accuracy. As more industries adopt this technology, it's becoming a standard part of daily operations, promising a safer and more efficient future for all.

Custom Ring Magnets,Neodymium Magnetic Ring,Custom Neodymium Magnets,Neodymium Grooved Magnets

Anfeng Industrial Co.,Ltd , https://www.afmagnets.com