Centrifugal Wheelblast vs. Air Blasting: Which One Fits Your Needs?

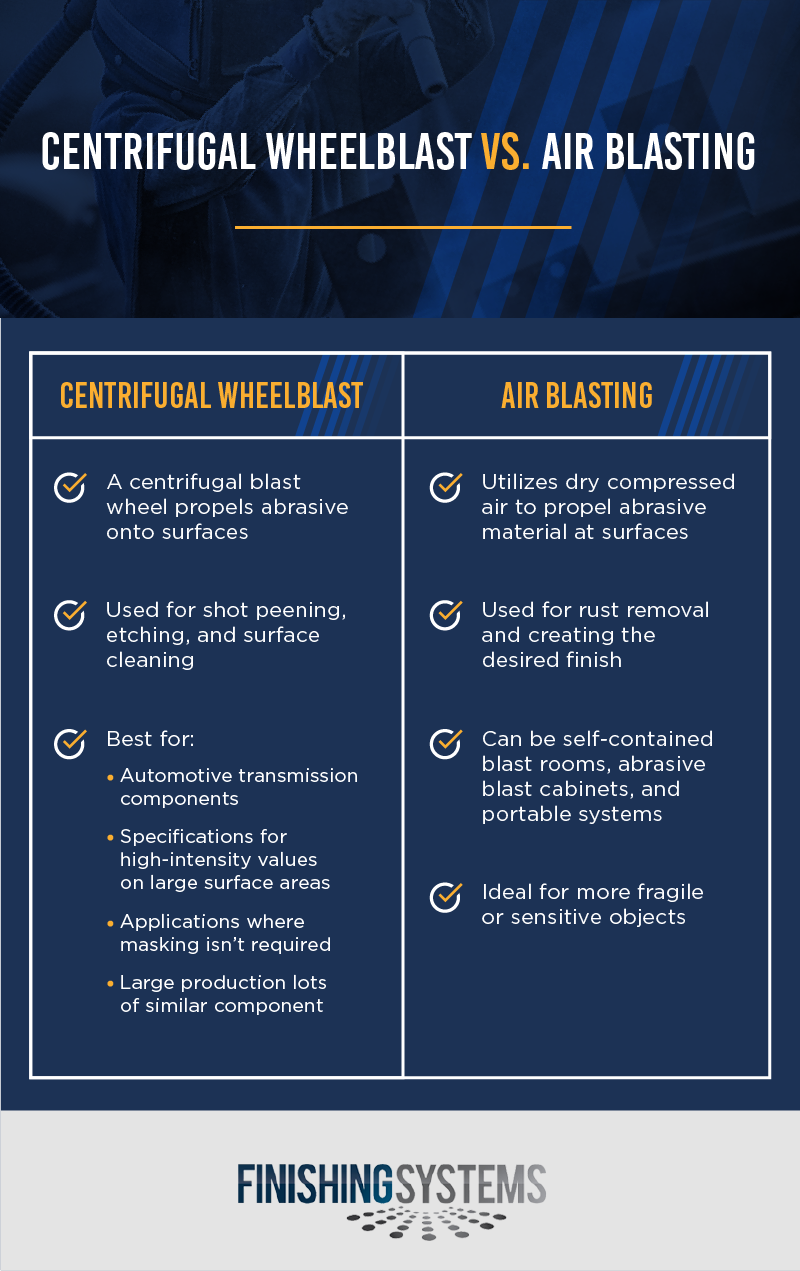

Last Updated: October 17, 2023Are you torn between choosing centrifugal wheelblasting or air blasting for your project? Both techniques involve propelling abrasive media onto metal components to remove scale, create texture, or clean surfaces. However, factors like the size, shape, and volume of your parts can significantly influence which method is ideal for achieving your desired outcome. Selecting the right equipment, process parameters, and media ensures optimal results while keeping costs low and efficiency high.

With so many options available, deciding which approach works best can feel overwhelming. If you're unsure whether wheel blasting or air blasting is right for your needs, this guide aims to simplify the decision-making process.

Get in Touch

Understanding Centrifugal Wheelblasting

Centrifugal wheelblasting employs a high-speed blast wheel to hurl abrasive material onto your components. This method is commonly used for tasks like shot peening, etching, and thorough cleaning. Unlike air blasting, which uses compressed air to propel smaller quantities of abrasive, wheelblasting relies on centrifugal force generated by the wheel to distribute the media evenly across the surface.

Wheelblasting systems typically feature direct-drive or belt-driven wheels mounted within a sealed chamber. The wheel's rotational speed determines the velocity of the abrasive particles and directly impacts the overall throughput. Modern variable frequency drives (VFDs) allow users to fine-tune the wheel's speed for specific applications.

This technique excels in scenarios requiring uniform coverage over large areas, particularly when processing large volumes of identical parts. Ideal candidates include automotive components like gears, shafts, and axles, as well as rail industry applications.

- Best suited for high-intensity treatments on extensive surfaces

- Appropriate for masking-free applications targeting complete surface coverage

- Optimal for mass production runs involving similar parts

In a typical wheelblasting setup, abrasive materials—often steel shot, grit, or specialty alloys—are fed into the machine while the components are placed inside the blast chamber. Once activated, the blast wheel distributes the abrasive uniformly across all exposed surfaces. This approach accommodates both small batches of smaller items or larger, single-piece loads. Short cycle times ensure rapid completion of the treatment.

For optimal performance, wheelblasting favors metallic abrasives such as steel shot, aluminum oxide, or stainless steel grit.

Exploring Air Blasting Solutions

Air blasting operates by channeling compressed air through nozzles to accelerate abrasive particles toward the target surface. Compressed air serves as the driving force behind this method, enabling precise control over the intensity and direction of the blast stream. Air blasting finds utility in diverse applications, ranging from light rust removal to achieving specific finishes on delicate surfaces.

Air blast systems come in several configurations, including self-contained blast rooms, enclosed cabinets (both direct-pressure and suction types), and portable units. Proper dust collection is critical in maintaining visibility and cleanliness during operation.

Finding the Right Fit for Your Project

Deciding between wheel blasting and air blasting ultimately depends on your specific requirements. Each method offers distinct benefits that may align more closely with certain projects than others.

One major advantage of wheel blasting lies in its speed and capacity. It can handle larger objects efficiently and is generally more cost-effective for high-volume operations. Conversely, air blasting provides greater flexibility in terms of precision and control, making it preferable for intricate or sensitive workpieces. For instance, a direct-pressure air blast cabinet allows operators to fine-tune the blast stream's pressure, ensuring minimal risk of damage while still delivering consistent results.

Ultimately, the choice hinges on balancing factors such as part complexity, production volume, and desired finish quality. Experimentation with various abrasives and techniques often proves invaluable in determining the best fit for your application.

Partner with Finishing Systems for Tailored Solutions

Still unsure which approach suits your needs? Or perhaps you're ready to invest in new equipment? Finishing Systems stands ready to guide you through the selection process. Our extensive range of blasting and finishing solutions ensures you'll find the ideal combination to meet your objectives.

For personalized assistance, contact us today.

Stainless Steel Special Silicone Sealant

Stainless steel special silicone sealant, silicone sealant, Stainless steel silicone sealant

Shandong Gufeng Technology Co., LTD. , https://www.gfkjgs.com