In this tutorial, we’ll walk you through the process of creating Gerber files and drill files from an Autodesk Eagle 9.6.2 CAD project. Gerber files are essential for PCB manufacturing, while drill files help define where holes need to be drilled in the board. This guide assumes you already have a basic understanding of Eagle CAD.

Generating Gerber, Drill Files, and Centroid Files (PnP Files)

To get started:

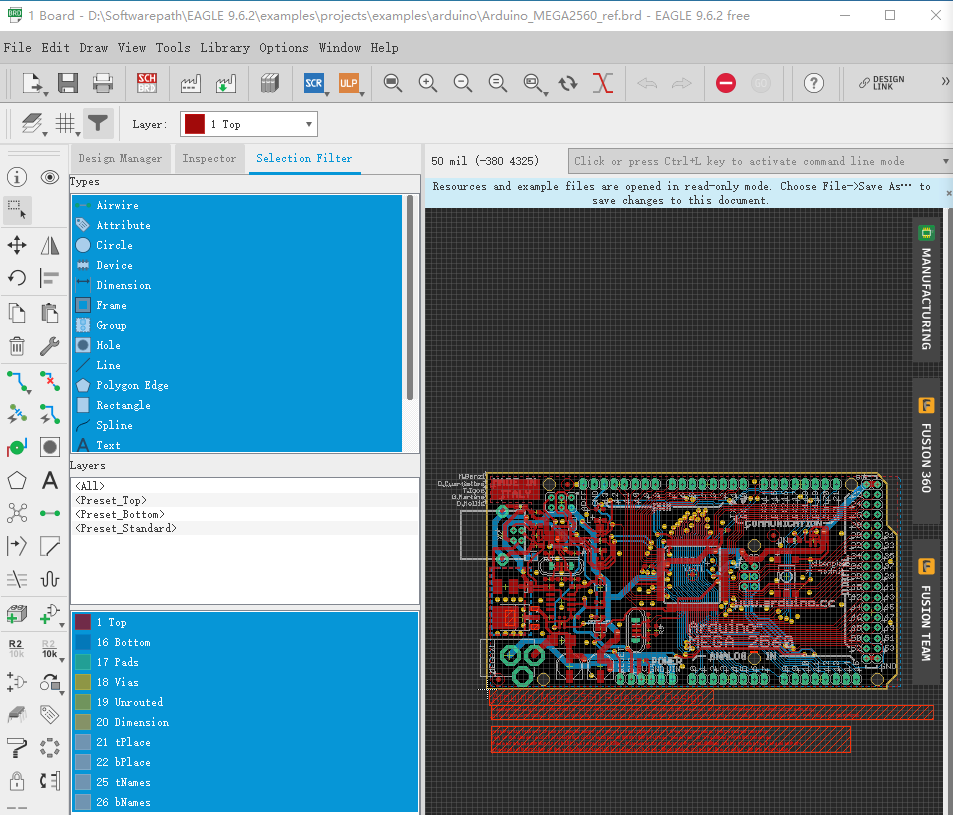

- Open the Control Panel in Eagle by clicking on the “Control†tab, then select “File†> “Open†> “Board.†Choose the .brd file you wish to work with. For this tutorial, we’ll use the Arduino MEGA2560 reference board provided by Eagle.

- Once you’ve opened the board file, a PCB layout window will appear, showing your design. It should look something like the image below:

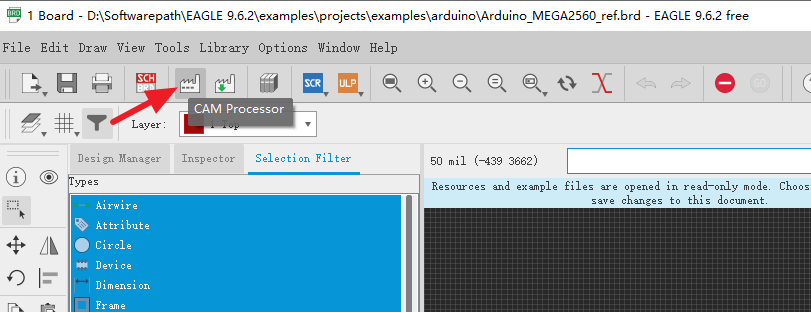

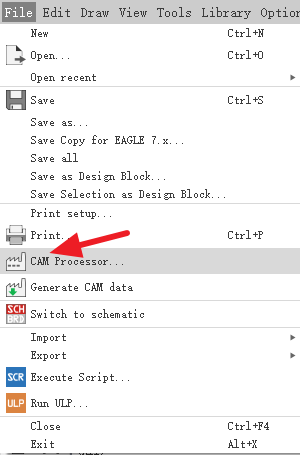

- Next, click on the CAM Processor button located on the toolbar (the one with no green arrow), or navigate to “File†> “CAM Processor.â€

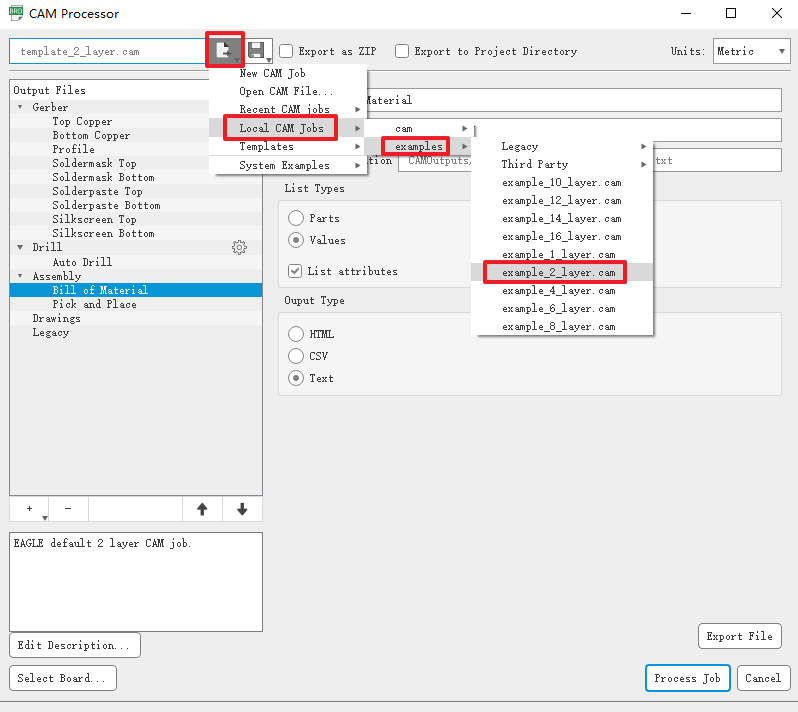

- After opening the CAM Processor, click on the document icon next to the CAM file name, then select “Load CAM jobs†> “Examples.†From here, choose the appropriate CAM job for your design. Since we’re working with a two-layer board, we’ll select “example_2_layer.cam.â€

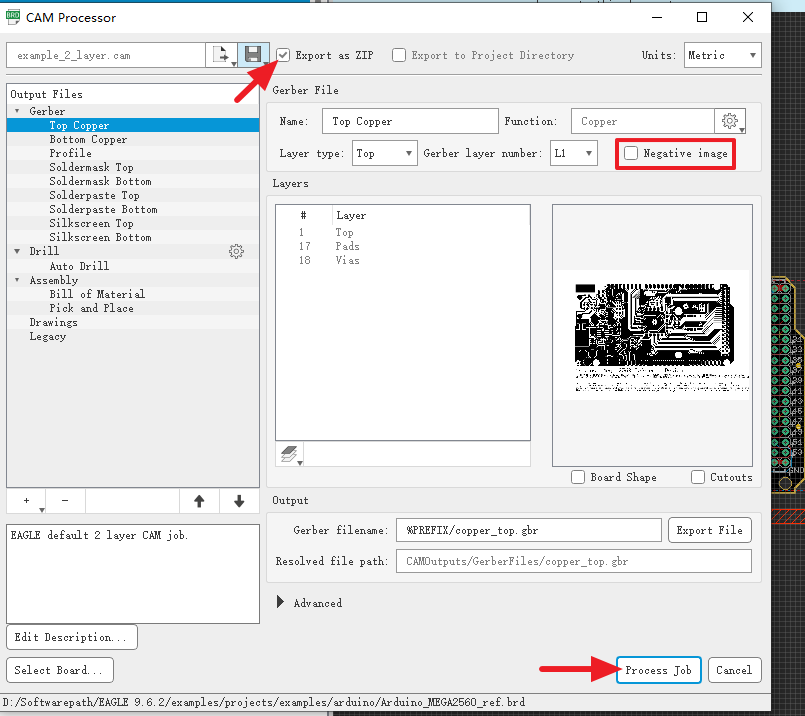

- On the right-hand side, use the Gerber previewer to inspect the data exported for each layer of the Gerber files. Make sure everything looks correct. Once satisfied, check the “Export as ZIP†option and click “Process Job†to continue.

Tips: Before exporting Gerber files, it’s highly recommended to run a Design Rule Check (DRC) to ensure there are no errors in your design that could cause issues during manufacturing.

Important Note: Ensure the “Negative Image†checkbox is unchecked, as highlighted by the red box in the following image:

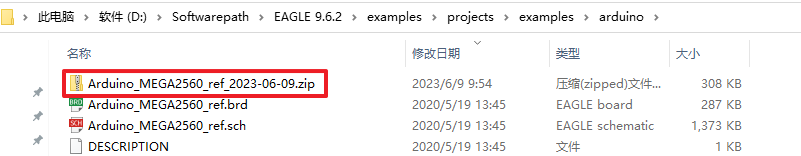

This action will generate a ZIP folder containing all the necessary Gerber files for your PCB.

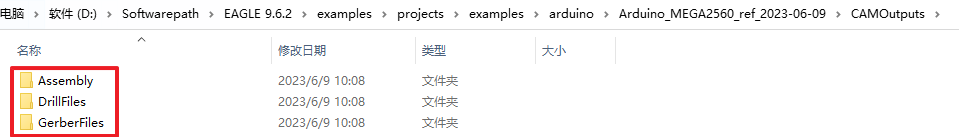

If you’d like to see what’s inside the ZIP folder, simply right-click on it and extract all the files.

With these steps completed, you’ve now successfully generated Gerber and drill files using Eagle 9.6.2. The centroid file (PnP file) can be found in the Assembly folder.

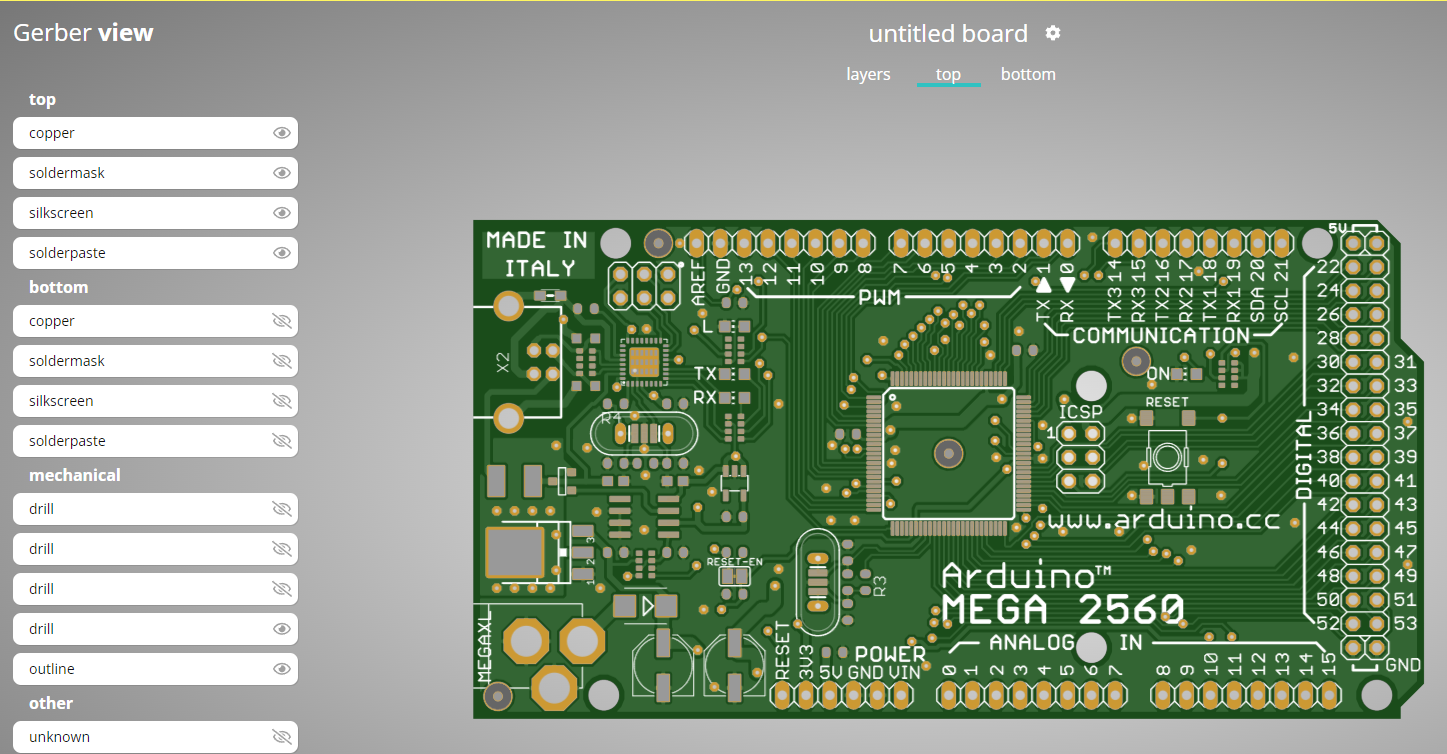

Previewing Gerber Files Using PCBWay Online Viewer

Once you’ve exported the Gerber and drill files, you can use the PCBWay Online Gerber Viewer to preview your designs:

For more information about the PCBWay Online Gerber Viewer, refer to the article titled "Finally, PCBWay’s Long-Awaited Online Gerber Viewer is Now Available."

RongNa has more than 10 years experience manufacturing custom machining and precision parts for diverse regional and national partners. Our working team uses the latest in CNC machining machine

We offer advanced 5-axis and 3-axis machining services that significantly increase the range of possibilities for working with complex surfaces and creating parts in numerous shapes and sizes. We provide custom Cnc Milling service and 3-axis, 5-axis CNC milling parts

How Does 5-axis CNC MILLING WORK?

Milling is the process of cutting and drilling material using a rotating cylindrical tool. This tool is held in a spindle and comes in a variety of sizes and forms. With 5-axis machining, there have two extra rotary axes defined by A, which rotates around the X axis, B, which rotates around the Y axis, and C, which rotates around the Z axis. The combination of additional axes depends on the machine and comes in variations, including AB, AC, or BC.

With 5-axis machining, the table or cutting tool can be tilted, creating the ability to avoid collision with the tool holder and allowing for better access to part geometry. This also ensures improved tool life and cycle time as it helps maintain cutting position and constant chip load. This type of machining offers a push toward single-setup machining, creating shorter lead times and increasing efficiency.

CNC milling is complex machining technique which utilizes several types of pre-programmed CAM and CNC controls to build customized components or parts. We are professional custom CNC milling company and 5 Axis CNC Milling Service provider in China, we offer the manufacturing of precision machined parts and solutions at affordable rates to meet the growing demands of the clients across the world.

We have several machining centers for creating complicated shapes or parts for your products. Contact for more.

Cnc Machining,Custom Cnc Machining,Cnc Machining Service,Cnc Metal Machining

Ningbo Rongna Technology Co.,Ltd , https://www.service-machining.com