Choosing the right aerospace fabrication partner is a critical decision that can significantly impact your project’s success. While cost is an important consideration, it shouldn’t be the only factor in your evaluation. A reliable partner should offer more than just competitive pricing—they should bring expertise, experience, and a proven track record of delivering high-quality results. This article provides procurement professionals with key questions to ask when evaluating potential aerospace metal fabrication partners.

A Brief Overview

Some companies specialize in large-scale production runs, offering cost-effective solutions for high-volume orders, while others focus on smaller, custom projects where flexibility and precision are essential. As a procurement professional, it's important to understand what each company offers and how their capabilities align with your specific needs. Start by identifying the scope of your project and the level of customization required before reaching out to potential partners.

Key Questions to Ask When Choosing an Aerospace Metal Fabrication Partner

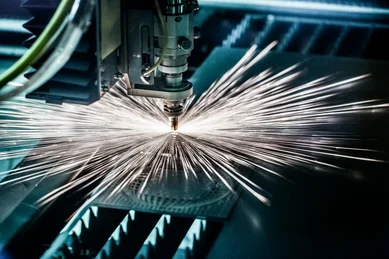

When working on aerospace projects, accuracy is non-negotiable. The right partner should have skilled technicians, advanced equipment, and a commitment to quality at every stage of the process. Here are some essential questions to consider:

Does the company have on-site testing capabilities? Accurate testing is crucial to ensure that parts meet the exact specifications required. Look for a fabricator that can perform in-house inspections and provide immediate feedback. This not only ensures quality but also helps identify issues early in the process, saving time and resources.

Can the fabricator handle the entire manufacturing process from start to finish? While some companies may work with multiple vendors, having a single partner that can manage all aspects—from raw material sourcing to final assembly—can streamline the process and reduce logistical challenges. Evaluate whether the company has the internal capabilities to complete the full cycle or if they rely on third-party suppliers for key steps.

To assess a company’s efficiency, a visit to their facility is highly recommended. Take note of the following during your tour:

- Is there a clear and organized workflow in place?

- Does the facility maintain a clean and well-managed environment?

- How do they plan and allocate work capacity?

- Is communication between departments smooth and effective?

What is the company’s level of engineering and consultation support? A great fabrication partner doesn’t just build parts—they collaborate with you to optimize designs and improve manufacturability. Look for a company that offers engineering support and is willing to provide insights that can enhance the performance and efficiency of your components.

It’s also beneficial to choose a partner that is open to continuous improvement. The best aerospace fabricators are those that actively seek ways to refine processes and reduce lead times. If a company is willing to adapt and innovate, they’re more likely to deliver long-term value.

CAMM Metals | CT Aerospace Fabrication

CAMM Metals specializes in precision manufacturing, producing machined parts with tight tolerances for the aerospace industry. With a strong focus on quality, innovation, and customer collaboration, we work closely with clients to develop solutions that meet even the most demanding requirements.

As the aerospace sector continues to evolve, we remain committed to staying at the forefront of manufacturing technology. Our team of engineers partners with customers to create innovative designs that solve complex challenges. From concept to completion, we ensure that every product leaving our facility meets the highest standards of quality and reliability.

Whether you need a custom part or a large production run, we are here to help. Contact us today at 860-292-6260 or request a quote to get started.

hbspt.cta._relativeUrls=true;hbspt.cta.load(2546019, 'e7d5e1de-1338-428a-a098-f6228bbbeb1d', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2546019, 'e7d5e1de-1338-428a-a098-f6228bbbeb1d', {"useNewLoader":"true","region":"na1"});

Plastic Screen Window/shade Net/ Plastic Geogrid

Plastic Screen window/shade net/ Plastic Geogrid

HEBEI CONQUER HARDWARE WIRE MESH CO.,LTD , https://www.anjiahardware.com