Types of Abrasive Materials

March 07, 2023When working with metal components, it's common to encounter impurities or imperfections that arise naturally or during the manufacturing process. These issues can complicate coating applications and other critical procedures, ultimately affecting the quality of the final product.

Abrasive blasting is a highly effective method for removing unwanted materials and preparing surfaces for further processing. This technique involves propelling a high-pressure stream of water mixed with abrasive particles to clean, etch, or texture the surface, ensuring a smooth and consistent finish.

There are numerous types of abrasive media available, each with unique properties that make them suitable for different applications. Choosing the right material can significantly impact the efficiency and outcome of your blasting project.

What Are the Different Types of Abrasive Media?

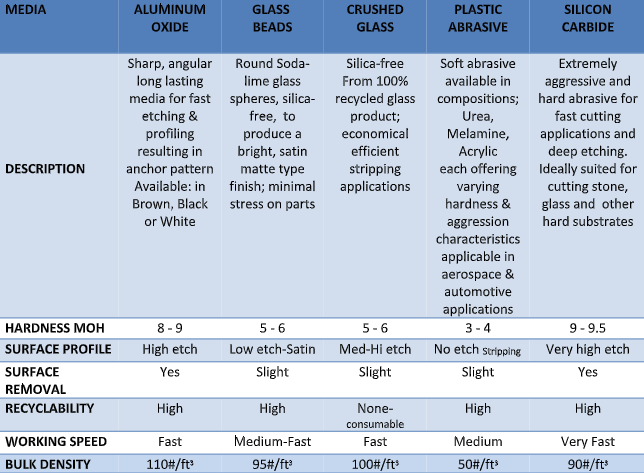

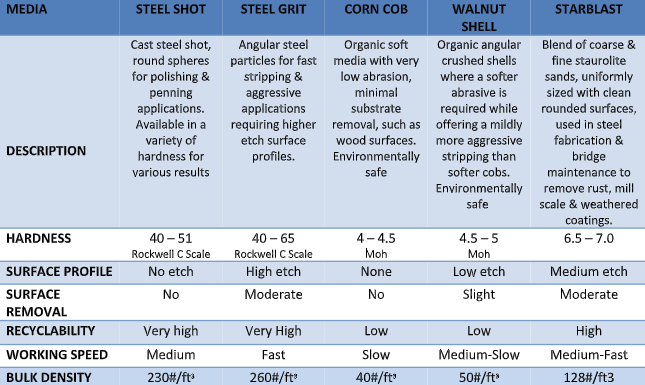

Here’s an in-depth look at the most commonly used abrasive media, along with their characteristics and typical applications:

- Glass Beads: Glass beads are a gentle yet effective abrasive option, ideal for achieving a bright and smooth finish. They are often used on stainless steel and can be recycled multiple times, making them both cost-effective and environmentally friendly.

- Aluminum Oxide: Known for its high hardness and durability, aluminum oxide is widely used in industrial settings. It is excellent for surface preparation before painting or coating, especially on metals like steel, glass, and stone.

- Plastics: Plastic abrasives are made from crushed urea, polyester, or acrylic and come in various hardness levels. They are perfect for delicate surfaces where minimal damage is required, such as in automotive and electronics industries.

- Silicon Carbide: As one of the hardest abrasives available, silicon carbide is ideal for heavy-duty applications. It is used in lapping, polishing, and cutting, and is particularly effective for tough materials like ceramics and composites.

- Steel Shot & Grit: Steel abrasives are durable and highly recyclable, making them a popular choice for many applications. They are effective for cleaning, texturing, and peening surfaces, especially in industrial environments.

- Starblast: Starblast™ is a low-silica blasting medium made from staurolite sand. It’s great for removing scale and rust from steel without creating excessive dust, improving visibility during the process.

- Walnut Shells: Made from crushed walnut shells, this natural abrasive is softer than other options and is ideal for polishing delicate materials like wood, plastic, and soft metals.

- Corn Cobs: Corn cob abrasives are a biodegradable option that works well for cleaning and deburring. They are often used in jewelry, engine parts, and graffiti removal due to their gentle yet effective nature.

The Evaluation Criteria

Choosing the right abrasive media depends on several factors, including:

- Hardness: Measured on the Mohs scale, hardness determines how aggressively the media will scratch the surface. Softer media is better for delicate materials.

- Surface Profile: The shape and size of the abrasive affect the texture left on the surface, which can range from no etch to deep grooves.

- Removal Rate: Some abrasives remove more material than others, so it's important to choose one that meets your project’s specifications.

- Recyclability: Reusable abrasives can help reduce long-term costs and environmental impact.

- Working Speed: Some media work faster than others, which can increase productivity.

- Bulk Density: This affects how quickly the abrasive cleans and the depth of the surface profile it creates.

Learn More About the Different Types of Abrasive Media

Finishing Systems offers a wide range of sandblast media tailored to meet various industrial needs. Our products come in different grit sizes and packaging options to suit your specific requirements. All our materials are designed to deliver consistent performance and reliable results.

Need help choosing the right abrasive media? Our team of experts is here to guide you through the selection process and ensure you get the best solution for your application.

Contact us today to learn more about our abrasive media solutions and get expert advice on your next project.

Injection Tooling & Mold Built

Injection Tooling & Mold Built,Plastic Part Injection Molding,Parts Injection Molding,Injection Molding

Wisegroup Precison Mold Ltd , https://www.wisegroupasia.com