In the industrial world, parallel shaft AC gear motors have long been the standard configuration. However, right-angle brushless gear motors are increasingly being adopted due to their ability to significantly reduce the physical footprint of machinery, such as conveyors.

One critical factor to consider is the type of gears used in the gearhead. While worm gear technology remains popular, its efficiency can fluctuate between 50% to 90% depending on the gear ratio. Conversely, hypoid gear technology maintains an efficiency range of 80% to 95%, irrespective of the gear ratio. Higher gear efficiency enables more torque to be transferred from the motor to the load shaft, sometimes allowing for the use of even smaller motors.

A perfect application example is depicted below where a parallel shaft gear motor is mounted on the side of a belt conveyor. You'll notice how the motor and gearhead extend beyond the conveyor's edge. This not only increases the machine's footprint but can also pose a safety hazard. Additionally, extra components like couplings and mounting plates are required for installation.

Conventional Equipment: An AC induction motor is installed on the conveyor alongside a parallel shaft gearhead and a coupling mechanism. Typically, an inverter (VFD) is employed for speed control (not shown).

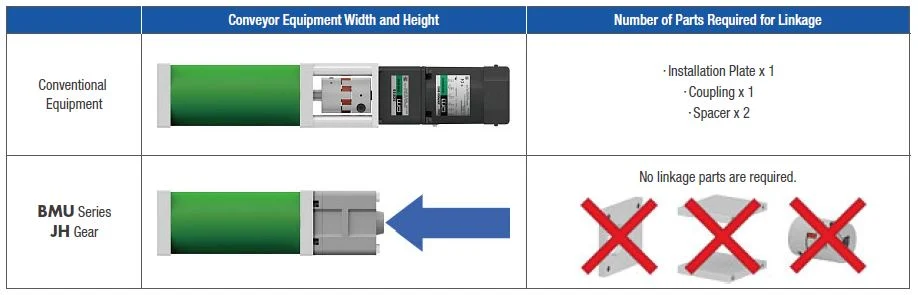

Issues with Conventional Equipment:

- The motor and transfer mechanism protruding from the side of the conveyor take up more space than necessary, making it difficult to add more conveyors side by side.

- A large number of parts and labor hours are required to install the motor onto the equipment.

- Parallel shaft gear motors generally use helical or spur gears, which are less efficient compared to hypoid gears.

SOLUTION : BMU Series brushless motor + JH gearhead + AC input driver

Utilize a compact yet powerful

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'b3b3c8e2-e5a0-450e-8933-a74809a5c4ae', {"useNewLoader":"true","region":"na1"});

(right-angle hypoid type)

to minimize the motor protrusion on the side of the conveyor. The efficient JH type gearhead also requires fewer components for installation, whether through face mount or using a torque arm. Since both brushless motors and JH gearheads are more efficient than AC motors and parallel shaft gearheads, the motor size and power consumption can be reduced. For ease of replacing AC motors and inverters (VFDs), we

Advantages provided by the BMU Series:

- The JH right-angle hypoid gearhead offers high rigidity, torque, and efficiency.

- Reduces motor protrusion.

- Smaller motor size.

- Options include face mount (left) or torque arm (above).

- Fewer components required for installation.

RESULTS : Reduced labor hours achieved by using fewer parts.

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'f940eda0-2e81-4092-991c-dd773d335b76', {"useNewLoader":"true","region":"na1"}); Discover how a right-angle gearhead can optimize machine design and installation

Read the next post to find out how much weight can be reduced by switching to brushless motors.

Also: hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '49c29b47-743a-4355-9d7f-0ce028ce652c', {"useNewLoader":"true","region":"na1"});

Conical Twin Screw Barrel For Pvc Pipe

pvc pipe

Conical Twin Screw Barrel For Pvc Pipe,50-105 Cincinnati Conical Twin,Theyshon Con63 Screw Barrel,Twin Screw Barrel Of Theyshon Con63

ZHOUSHAN BATTEN IMPORT AND EXPORT CO.,LTD. , https://www.battenscrew.com